MPO Fiber Optic Solutions – The Key to High-Density, Reliable Networks

Introduction

In today’s fast-growing digital economy, businesses and telecom operators face increasing pressure to deliver faster, more reliable, and higher-capacity networks. Data centers are expanding, 5G is accelerating, and fiber-to-the-home (FTTH) projects are rolling out worldwide. For network builders, importers, and distributors, the challenge is clear: how to manage fiber optic connections efficiently, cost-effectively, and at scale.

This is where MPO fiber optic solutions come in. MPO (Multi-Fiber Push-On) connectors and related products are designed to provide high-density connectivity in a compact, reliable, and easy-to-deploy format. Unlike traditional fiber connectors that handle only one fiber per ferrule, MPO connectors can manage 12, 24, or even 48 fibers in a single connection. This saves time, reduces installation costs, and simplifies network expansion.

For B2B buyers, understanding the role of MPO in the fiber optic supply chain is crucial. Whether you are sourcing MPO patch cords, jumpers, PLC splitters, distribution boxes, or patch panels, these solutions are no longer optional—they are essential for building networks that meet the demand for speed and stability.

What is MPO in Fiber Optics?

MPO stands for Multi-Fiber Push-On, a standardized fiber optic connector that allows multiple fibers to be terminated in a single rectangular ferrule. Developed to meet the growing demand for high-bandwidth applications, MPO has quickly become the preferred choice in data centers, telecom networks, and fiber-to-the-x (FTTX) projects.

Unlike single-fiber connectors such as LC or SC, which require individual patching for each fiber, an MPO connector groups fibers together, drastically reducing installation time and minimizing the space needed in racks or cabinets. For example:

A 12-fiber MPO patch cord can replace 12 separate LC patch cords.

A 24-fiber MPO jumper can handle double the capacity in the same footprint.

Key Features of MPO Connectors in Fiber Optic Networks:

High Fiber Count: Supports 12, 24, 36, or 48 fibers in a single connector.

Compact Design: Ideal for high-density environments like data centers and backbone cabling.

Versatile Use: Compatible with patch cords, jumpers, PLC splitters, distribution boxes, and patch panels.

Scalable Performance: Designed for single mode and multimode fiber optic applications, making them suitable for both short-distance LAN and long-haul telecom networks.

In short, MPO is not just a connector—it’s a complete fiber optic solution that makes network deployment faster, more organized, and future-proof.

MPO Fiber Optic Product Range

When it comes to fiber optic connectivity, having the right products is just as important as choosing the right network design. For importers, distributors, and project managers, understanding the MPO product portfolio helps in making better purchasing decisions. Below are the most in-demand MPO fiber optic products that are widely used in data centers, FTTX projects, and telecom infrastructures.

MPO Patch Cord & MPO Jumper

The MPO patch cord (also called an MPO jumper) is one of the most essential components in high-density fiber optic cabling. Unlike traditional LC patch cords or SC patch cords, which connect only one fiber at a time, an MPO patch cord connects multiple fibers simultaneously.

Key Benefits for Buyers:

Efficiency: A 12-fiber MPO jumper can replace 12 single-fiber cords, reducing cable clutter.

Time-Saving: Pre-terminated MPO patch cords allow faster installation and easier moves, adds, and changes (MACs).

Flexibility: Available in single mode and multimode versions, armored or non-armored, and in custom lengths.

Compatibility: Works seamlessly with MPO patch panels, MPO distribution boxes, and PLC splitters.

For distributors, stocking MPO patch cords is a must, since they are a high-turnover item required in nearly every fiber optic project.

MPO PLC Splitter

The MPO PLC splitter is designed to divide or combine optical signals in fiber optic networks. In FTTX and passive optical networks (PON), splitters play a critical role in ensuring stable and balanced signal distribution.

Why MPO PLC Splitters are in Demand:

Compact Design: MPO interfaces make installation in limited space environments more efficient.

Reliable Performance: Ensures low insertion loss and uniform signal splitting.

Customization Options: Ratios like 1×2, 1×4, 1×8, 1×16, 1×32, and 1×64 are available with MPO terminations.

Ease of Integration: Fits easily into MPO distribution boxes and patch panels for organized network setups.

For wholesalers and importers, MPO PLC splitters are a smart investment because they are critical in FTTH, 5G, and backbone fiber optic applications.

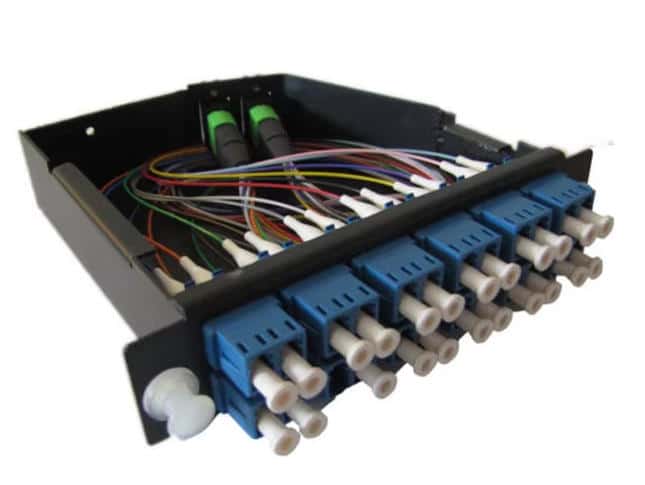

MPO Distribution Box

An MPO distribution box is a compact enclosure that provides protection, management, and distribution for fiber optic connections. Designed for indoor and outdoor use, it simplifies field installations and is widely used in multi-dwelling units (MDUs), ODN, and FTTH rollouts.

Advantages of MPO Distribution Boxes:

Pre-terminated Options: Plug-and-play solutions save time and labor costs.

Weatherproof Models: Outdoor-grade boxes are resistant to dust, moisture, and UV.

Scalability: Available in various fiber counts to suit small to large projects.

Integration: Easily houses MPO patch cords, jumpers, and PLC splitters for a complete solution.

For network builders, choosing an MPO distribution box means faster deployment and lower total cost of ownership.

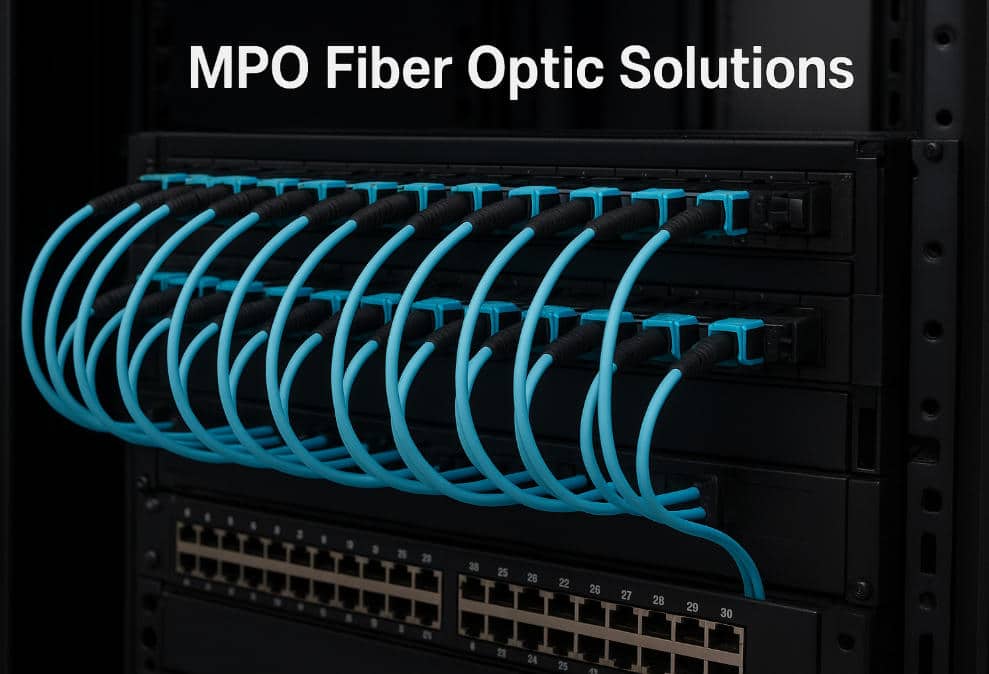

MPO Patch Panel

The MPO patch panel is the backbone of fiber optic cable management in data centers and telecom facilities. It allows technicians to neatly organize MPO connections, ensuring stable performance and simplified maintenance.

Why MPO Patch Panels Are Essential:

High Density: Accommodates a large number of fibers in a compact space.

Organization: Keeps MPO patch cords and jumpers structured, avoiding messy cabling.

Flexibility: Supports mixed connections (MPO to LC/SC) with modular cassettes.

Scalability: Easy to expand as network capacity grows.

For procurement managers, investing in MPO patch panels ensures not only neat cable management but also long-term reliability.

Advantages of MPO Fiber Optic Solutions

When making sourcing decisions in the fiber optic industry, buyers, importers, and project managers must always evaluate the value and performance of the products they invest in. MPO fiber optic solutions stand out because they offer a unique balance of high density, scalability, cost-effectiveness, and reliability.

Here are the main reasons why MPO patch cords, jumpers, PLC splitters, distribution boxes, and patch panels have become the go-to choice for modern network builders.

1. High-Density Connectivity

One of the greatest challenges in today’s data centers and telecom networks is space. Equipment racks and cabinets are limited, yet fiber demands continue to grow. MPO connectors address this challenge by grouping multiple fibers into a single compact connector.

A 12-fiber MPO patch cord can replace 12 traditional LC patch cords.

A 24-fiber MPO jumper handles double the capacity without increasing footprint.

When combined with MPO patch panels and distribution boxes, buyers gain structured, high-capacity management in minimal space.

For importers and distributors, this advantage translates into products that sell themselves—customers are constantly searching for higher-density solutions.

2. Faster Installation and Deployment

Time is money in fiber optic projects. Traditional fiber terminations are labor-intensive, requiring technicians to install one fiber at a time. With pre-terminated MPO patch cords and jumpers, dozens of fibers can be connected in a single step.

Plug-and-play design speeds up rollout.

Pre-terminated MPO distribution boxes reduce on-site labor costs.

MPO patch panels allow fast moves, adds, and changes (MACs).

For project managers, this means reduced installation time and labor costs, which is a powerful selling point when bidding on large contracts.

3. Scalability for Future Growth

Networks evolve quickly. What may be sufficient today could be outdated tomorrow. The good news is that MPO fiber optic solutions are designed for long-term scalability.

Easy Upgrades: Existing MPO patch panels can be expanded by simply adding more MPO cassettes.

Flexible Configurations: MPO jumpers and patch cords support both single mode and multimode applications.

Future-Proof Design: MPO solutions are ready for 40G, 100G, and even 400G networks.

For buyers, scalability means longer product lifecycle and higher ROI—your customers won’t need to replace infrastructure every time capacity needs grow.

4. Cost-Effectiveness

At first glance, some procurement managers may think MPO is more expensive than traditional connectors. However, when considering the total cost of ownership, MPO proves to be far more economical.

Reduced Material Costs: Fewer patch cords, jumpers, and panels are required.

Lower Installation Costs: Less labor, faster deployment.

Simplified Maintenance: Easy identification and management lowers long-term expenses.

Importers who offer MPO solutions gain a competitive edge—because they deliver not just a product, but a cost-saving solution.

5. Reliable Performance

Ultimately, the success of any fiber optic network depends on stability. MPO connectors and assemblies are engineered for low insertion loss, high return loss, and stable optical performance.

MPO PLC splitters ensure uniform and reliable signal distribution.

MPO distribution boxes protect fibers from dust, moisture, and physical stress.

MPO patch panels keep cabling structured, reducing the risk of downtime.

For wholesalers and distributors, promoting reliability builds trust with end-users and ensures repeat orders.

MPO vs. LC/SC Connectors and Patch Panel Solutions

When sourcing fiber optic products, buyers often ask: “Why should I invest in MPO when LC or SC connectors are cheaper and more common?” The answer lies in understanding the strengths and limitations of each option. While LC and SC patch cords remain popular in many fiber optic networks, MPO connectors, jumpers, distribution boxes, and patch panels deliver clear advantages in high-density and high-speed applications.

Comparison at a Glance

| Feature | MPO Connector & Solutions | LC Connector | SC Connector | Patch Panel |

|---|---|---|---|---|

| Fiber Capacity | 12–48 fibers per connector | Single fiber | Single fiber | Modular, varies |

| Density | Very high (compact, multi-fiber) | Medium | Medium | High (depends on module type) |

| Deployment Speed | Fast (pre-terminated) | Slower (1 fiber at a time) | Slower (1 fiber at a time) | Moderate |

| Space Efficiency | Saves rack/cabinet space | Requires more space | Requires more space | Efficient if modular |

| Scalability | Easy to expand | Limited | Limited | Flexible |

| Applications | Data centers, 5G, backbone, FTTX | FTTH, enterprise LAN | FTTH, CATV, telecom | Data center & telecom cable management |

| Cost Perspective | Higher upfront, lower total cost | Lower upfront, higher labor cost | Lower upfront, higher labor cost | Medium cost depending on design |

When to Choose MPO

High-Density Data Centers: MPO patch cords, jumpers, and patch panels provide unmatched density and organization.

5G and Telecom Rollouts: MPO distribution boxes and PLC splitters speed up deployment and ensure scalability.

Future-Proof Projects: Networks planning to support 40G/100G/400G need MPO today to avoid expensive upgrades tomorrow.

When to Choose LC/SC

Small-Scale Networks: LC and SC patch cords are cost-effective for enterprises with low fiber counts.

Point-to-Point Applications: SC and LC are simple and reliable for direct connections in FTTH and LANs.

Budget-Conscious Buyers: If density and scalability aren’t priorities, LC and SC remain viable.

The Role of Patch Panels

It’s worth noting that patch panels complement both MPO and LC/SC systems. For large networks, MPO patch panels are essential to manage multi-fiber connections, while modular panels can also integrate LC and SC connections. Importers and distributors should carry a mix of MPO patch panels and traditional panels to meet varied customer demand.

Buyer Takeaway

For procurement managers and importers, the real decision comes down to application and future needs. While LC and SC patch cords remain important in FTTH and enterprise networks, MPO fiber optic solutions—patch cords, jumpers, PLC splitters, distribution boxes, and patch panels—deliver long-term value in high-density and high-growth markets.

By stocking MPO, you position your business as a future-ready supplier, able to serve customers who demand more capacity, less downtime, and faster installations.

Applications of MPO in Modern Networks

The demand for MPO fiber optic solutions is being driven by the rapid expansion of high-bandwidth applications worldwide. From hyperscale data centers to nationwide FTTX rollouts and 5G deployments, MPO products—such as patch cords, jumpers, PLC splitters, distribution boxes, and patch panels—are essential for building reliable and scalable infrastructures.

Below are the key industries and scenarios where MPO plays a critical role.

1. Data Centers

Data centers are the heart of the digital economy. They handle massive volumes of data from cloud services, video streaming, e-commerce, and enterprise applications. In these environments, high density and high-speed connectivity are critical.

MPO Patch Cords & Jumpers: Enable quick and efficient backbone cabling between switches, servers, and storage systems.

MPO Patch Panels: Keep fiber organized, making it easier for technicians to manage thousands of connections.

Scalability: MPO solutions support 40G, 100G, and even 400G Ethernet, making them future-proof.

For buyers and distributors, MPO products for data centers are high-value items with strong and consistent demand.

2. 5G Networks and Telecom Infrastructure

The rollout of 5G networks requires massive investments in fiber optic infrastructure to deliver ultra-low latency and high bandwidth. Unlike older mobile technologies, 5G depends heavily on dense fiber connections.

MPO Distribution Boxes: Allow fast field installation and protection of connections in telecom towers and street cabinets.

MPO PLC Splitters: Ensure balanced signal distribution across multiple cell sites.

MPO Patch Cords & Jumpers: Simplify backbone connectivity between core and edge equipment.

For importers, supplying MPO solutions to telecom operators is a strategic opportunity—5G growth guarantees strong purchasing volumes.

3. FTTX and FTTH Deployments

Governments and telecom companies worldwide are accelerating fiber-to-the-home (FTTH) and fiber-to-the-x (FTTX) projects to meet the growing demand for high-speed internet. MPO products are vital in ensuring quick and cost-effective rollouts.

MPO PLC Splitters: Divide signals to serve multiple homes or buildings.

MPO Distribution Boxes: Provide protection and easy access points for installers.

Pre-terminated MPO Jumpers: Reduce installation time in the field.

For wholesalers, stocking MPO-based FTTX products ensures they are aligned with one of the fastest-growing segments of the fiber optic market.

4. Enterprise Networks and Campuses

Large enterprises, universities, hospitals, and industrial facilities are also adopting MPO fiber optic solutions to handle increasing data loads and provide reliable connectivity.

MPO Patch Panels: Centralize fiber connections for efficient management.

MPO Patch Cords & Jumpers: Connect critical equipment in LANs and private data centers.

MPO Distribution Boxes: Protect outdoor and campus fiber runs.

These organizations value cost-effectiveness and scalability, making MPO an attractive choice compared to traditional fiber solutions.

5. International Wholesale & Import Markets

Beyond direct applications, the global fiber optic supply chain depends on reliable MPO products. Importers, distributors, and system integrators need a complete MPO product portfolio—patch cords, jumpers, PLC splitters, distribution boxes, and patch panels—to stay competitive in their local markets.

By sourcing directly from a trusted manufacturer, wholesalers can ensure stable supply, better pricing, and long-term partnerships.

Why Work with a Trusted MPO Fiber Optic Supplier

For procurement managers, importers, and distributors, choosing the right supplier is as important as choosing the right product. In the competitive fiber optic market, working with a trusted MPO supplier ensures that your investments translate into long-term performance, satisfied customers, and repeat business.

When evaluating MPO fiber optic suppliers, consider the following factors.

1. Quality Assurance

Fiber optic networks demand precision. Even a small defect in an MPO patch cord or PLC splitter can lead to signal loss, downtime, and costly repairs. That’s why quality control is non-negotiable.

Strict Testing Standards: A reliable supplier tests all MPO patch cords, jumpers, and splitters for insertion loss and return loss.

Durability: MPO distribution boxes and patch panels must meet international standards for mechanical strength and environmental protection.

2. Customization Capabilities

Every project has different requirements. A one-size-fits-all approach rarely works in fiber optic deployments. The best MPO suppliers offer customized solutions:

Patch Cords & Jumpers: Custom lengths, fiber counts, and connector types (single mode or multimode).

PLC Splitters: Flexible configurations (1×2 up to 1×64) with MPO terminations.

Distribution Boxes & Patch Panels: Tailored designs for indoor, outdoor, or rack-mounted use.

For importers, offering customized MPO products helps win larger projects and strengthens long-term client relationships.

3. Competitive Pricing

Cost is always a key factor in B2B procurement. While MPO solutions may carry a slightly higher upfront cost than traditional connectors, they deliver better value over time through lower installation costs, faster deployment, and scalability.

Working directly with a trusted fiber optic manufacturer gives buyers:

Factory Pricing: Eliminating middlemen increases profitability.

Bulk Discounts: Ideal for distributors supplying telecom operators and contractors.

Consistent Supply: Prevents delays in large-scale projects.

4. Global Trust and Proven Track Record

In the international fiber optic market, reputation matters. A reliable supplier should have a history of serving global importers, wholesalers, and telecom operators with consistent quality and service.

Strong References: Trusted by clients in data center, telecom, and FTTX sectors.

Stable Partnerships: Long-term cooperation with repeat orders.

After-Sales Support: Technical assistance, documentation, and responsive service.

Choosing such a supplier ensures peace of mind, knowing your MPO patch cords, jumpers, PLC splitters, distribution boxes, and patch panels will perform exactly as promised.

As networks continue to grow in speed and complexity, MPO fiber optic solutions are no longer optional—they are essential. Importers and distributors who invest in MPO patch cords, jumpers, PLC splitters, distribution boxes, and patch panels position themselves as leaders in their markets.

👉 If you are seeking a reliable MPO supplier with competitive pricing, proven quality, and full customization support, now is the time to act. Partner with a trusted fiber optic manufacturer and gain an advantage in today’s fast-moving telecom industry.