The fiber Distribution box is a common product in FTTH and FTTB. It protects the connection point of the optical cable to access user end, makes the optical cable access point stable, dust-proof, and waterproof. It reduces the interference for access signal of the optical cable to the external environment as much as possible.According to the different requirements of the actual application environment, there are many kinds of fiber distribution boxes on the market, how to choose? The following 10 points help you to understand everything about the fiber distribution box.

Table of Contents

1. The position of the fiber distribution box in the optical fiber communication

The transmission of the optical signal in the optical fiber is just like the flow of tap water in the water pipe. During the transmission process, when a user needs, it needs to be shunted to the user, but the shunt node needs a protection to prevent the tap water from leaking and forming.The node protection device that shunts the optical signal is called the fiber distribution box. This is its position in optical communication field.

2. Application scenarios of fiber distribution box

The optical network signal to the end user is generally divided into three scenarios, FTTH, FTTB, and FTTC, which are the last kilometer projects of optical fiber communication. The installation positions of the fiber distribution boxes in the three scenarios are also different. FTTH is on the floor. In the corridor, FTTB is on the wall of the building, FTTC is generally installed on the pole of the rural pole.

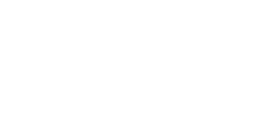

3. Internal structure of fiber distribution box

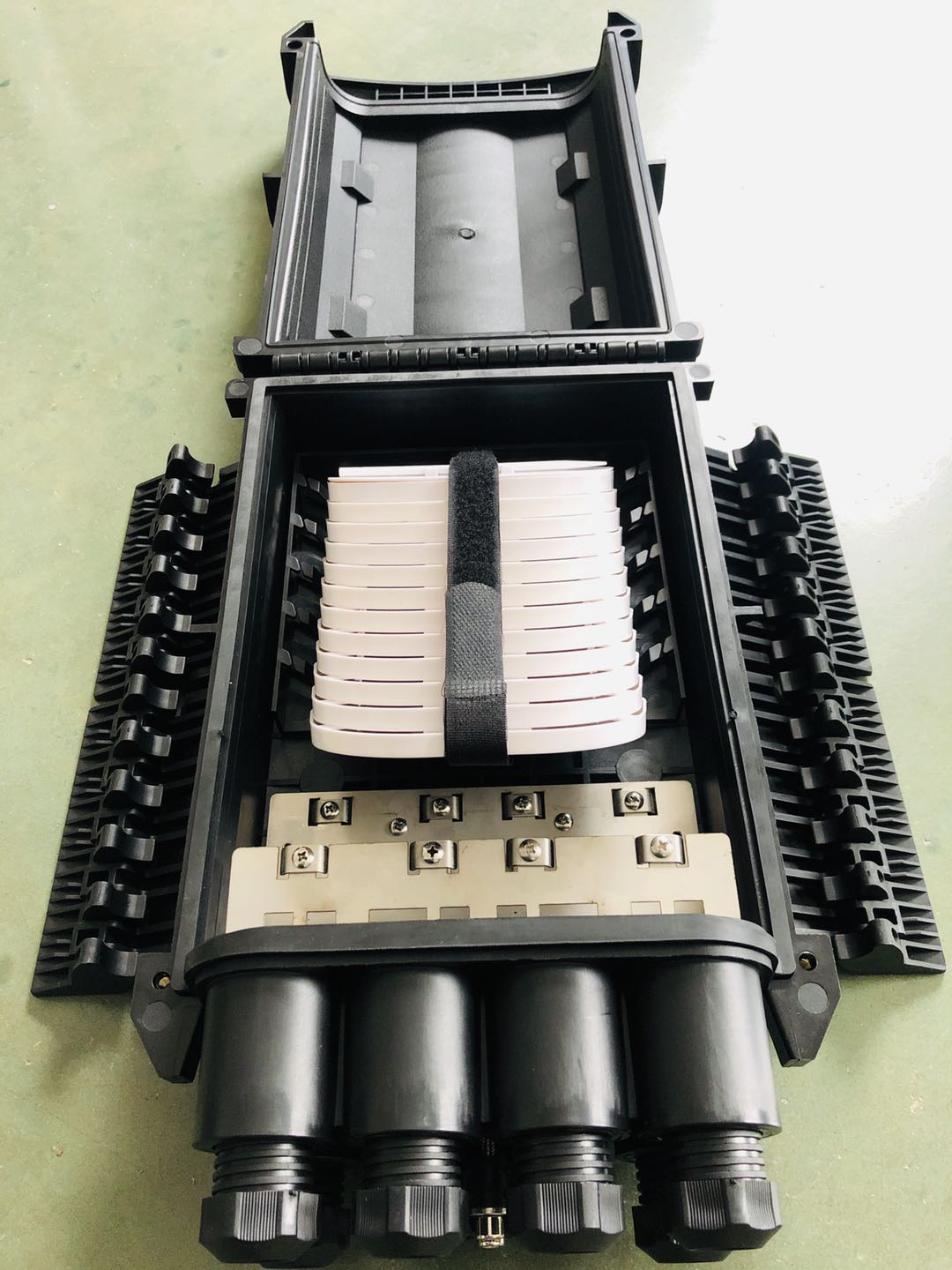

The function of the fiber distribution box is mainly to protect and split the fiber. Then its structure is divided into four parts,

- Cable inlet: This interface is mainly used for external optical cable access. The inserted optical cable plays a fastening role at the access port and is not easy to loosen. And the cable inlet is generally under the fiber distribution box, which has better waterproof effect.

- Splice tray: The external optical cable should be welded with the splitter or the headless end of the pigtail in the fiber distribution box, splice tray is necessary,which is convenient for welding and improves the success rate of welding.The thin card slot in the picture is for splicing the optical fiber after alignment.

- Fiber splitter disks: Some fiber splitter disks are available in some models, and some are not, because this only acts as a fixture and makes it more convenient and compact when installing splitters and pigtails. You can see various shapes of the fiber distribution tray and fusion splice tray in different kinds of fiber distribution boxes,But the function is same, it’s just the result of continuous improvement to make fibre fusion and cabling more convenient in practical applications.

- Outlet: the number of outlets can determine the basic model of a distribution box, such as 8 outlets, then it is basically 8-core distribution box, the outlet is much smaller than the inlet port, because the cable received from the user side of the fiber optic jumper or pigtail-based, the diameter of these wires are much smaller.

4. Classification of fiber optic distribution box

According to the capacity,fiber distribution box can be divided into: 4 core, 6 core, 8 core, 12 core, 16 core, 24 core, 36 core, 48 core and so on. The 8-core and 16-core are the most used.

According to the installation mode: can be divided into wall-hanging type and holding pole type.

According to the application scene: can be divided into indoor and outdoor type.

According to function: It can be divided into ordinary distribution (caja) box and distribution (caja) box with splicing function.

5. Material of fiber distribution box

At present, the materials used by mainstream distribution box are: SMC, ABS+PC, ABS, PP.The quality of the four materials is in order from good to bad, and the cost is from high to low.The differences in quality between the materials are in terms of material density, gloss, heat resistance, impact resistance, compression resistance, abrasion resistance and flame resistance.The most cost-effective of the four materials is ABS+PC, which is capable of meeting most of the material requirements of fibre distribution boxes at a moderate cost.

Although the SMC fiber distribution box is of high quality, but mainly used in extremely harsh environments, and high cost, the product market is not large.Due to the market competition is very sharp, product prices are getting lower and lower, the lower cost of pure ABS material distribution box occupies most of the market, so that the overall performance of the product is slightly decreased.PP material is the lowest performance, more brittle texture, generally used to make joint box, if used as a distribution box, the distribution box is certainly not over the impact test.

Personal recommendation for four kinds of material distribution box : if customers prefer quality, recommended PC + ABS, if customers prefer the price, recommended pure ABS material. Take the mainstream 16-core fiber distribution box for example, each box uses 1KG of material, the cost difference between the two materials is around 0.5USD. But it is difficult for people to distinguish the difference between these two materials, need professional testing, or good communication and cooperation of the manufacturer.

6. Manufacturing process and technology of fiber distribution (caja)box

Clarify the customer’s application requirements; if the existing product catalog can meet the requirements, we will produce according to the existing product flow.

- Drawings: If the customer needs non-conventional products, we will draw drawings for the product structure design according to the customer’s needs. Mold die-open: simple mold can be successfully opened in half a month, complex mold need at least one month.

- Injection molding: the speed of injection molding depends on the number of injection molding machines and the number of pieces molded at one time. A good manufacturer has injection molding machines that can mold 2000-3000 boxes per day, and can mold them quickly with a reliable delivery time.

- Assembly: This process is the manual part and is the most differentiated part of the factory. Skilled and qualified workers, optimized processes and norms, and strict management are the hallmarks of a good manufacturer.

- Testing and packaging: good production is to have back-testing on every part of production, from the previous process to the next, always with a test in between. The previous process is tested for completeness. The cycle continues to the final test where all processes are completed.

The packaging focuses on product protection and aesthetics and tidiness, the packaging of individual products must be measured, only single-item weight same to avoid missing accessories. The overall packaging focuses on the stability of the transport process and the convenience of receiving goods after arrival.

7. how to choose between full-loaded distribution box and empty distribution box?

In actual customer demand, there is a difference between full-loaded and empty boxes, some clients need box with splitter, adapters or pigtails installed . In addition, some clients only need empty box, customer will install splitter and other passive components according to the actual application scenario of field.

In general, the customer construction requirements are clear, unified specifications, it is recommended to use a full-loaded of the splitter box. If the customer’s requirements are more uncertain and require flexible handling, then an empty box can be used.

What is the advantage of a full-loaded distribution box? If splitter, adapters, pigtails are purchased uniformly, can save cost.In addition, the factory can assemble, test, and save labor costs, and the unified testing after factory assembly can eliminate the quality problems caused by the assembly process.

The factory calls this assembly process “fix splitter”. Good manufacturers will test the light of the splitter before it’s fixed, so that the quality problem of the splitter of the entire fiber distribution box can be eliminated.

After the splitter is installed, test it again. , To rule out the damage caused by artificial disc fiber. Moreover, the”fix splitterr” of the factory assembly line platform is easier and more efficient than the “fix splitter” constructed outdoors. The empty box distribution box is simple to inspect and the delivery time is faster. However, later construction costs are higher.

8. Quality inspection

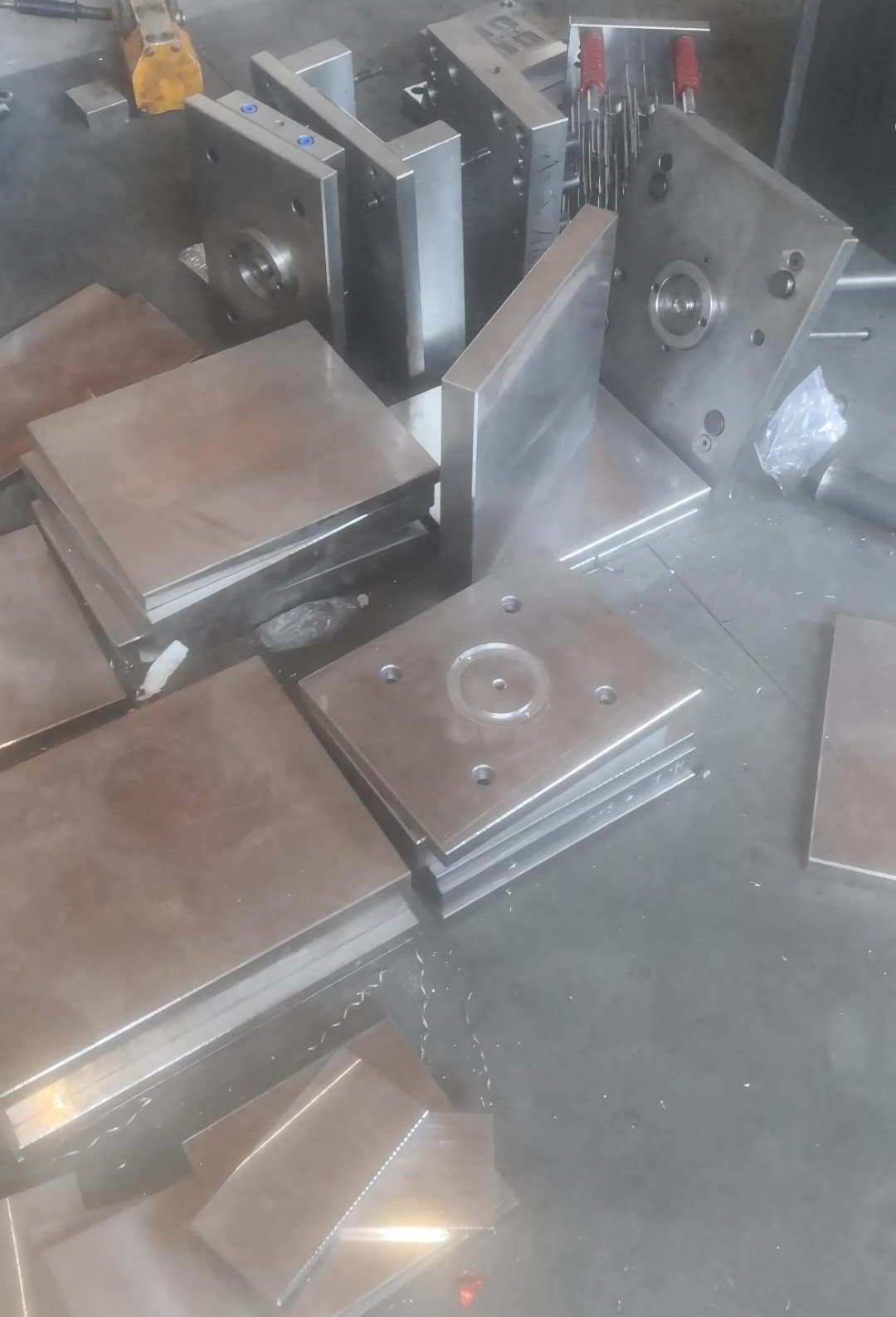

Generally, the quality test of the fiber distribution box is mainly waterproof, dustproof test, impact test, some require high and low temperature, humidity test, full-loaded distribution with splitter, pigtail also need to do fiber-pass test.

The requirements for dustproof and waterproof are high, because the outdoor environment is dusty, rainy and snowy, so the IP level must be at least IP65. The IP level is shown in the following figure.

Since dust affects the light transmission data, the dust must reach level 6, and the waterproof only needs to be level 5, because the wall-mounted or pole-type can basically avoid the rain soaking situation.Another fiber distribution box with joint function, its application environment is mainly in the sewer or buried construction, so its protection level must reach IP68.

The impact test mainly tests the physical compression performance of the product. Some fiber boxes with poor materials or injection thicknesses will not pass the impact test.

For full-loaded distribution box with splitter or pigtail, it is easy to break the fragile optical fiber during transportation and assembly, and it is difficult to find with the naked eye, the light test can exclude the fiber broken device.

9. Market and Price

The fiber distribution box belongs to the FTTX scene product and belongs to the user access terminal. In the face of countless users, its demand is higher than that of active optical device products. The market demand is rigid and the quantity is large.

There are many levels of price distribution boxes, mainly due to the different production standards and test standards of the suppliers. It is recommended not to choose the lowest price in the market to find fiber optic vendors.

All suppliers are merchants and need profit margins to ensure the operation and profitability of the factory . Products below the average price level are either low-quality products or a marketing strategy.Factories has a hundred ways to reduce costs. They can use different materials, different brands of materials, the amount of materials, the simplification of the production process and so on.

Therefore, clarify your own demand standards, determine the inspection standards with the manufacturers, and then discuss the prices on this basis. Talking about the price is enough, leaving some profit space for the other party, and the subsequent communication and cooperation will be smoother.

Generally speaking, if the demand is not large, if the number of fiber distribution boxes is less than MOQ, no need to find the factory directly. The better the factory orders, the smaller the quantity, they will not be given priority, and the production line replacement also requires cost. So the price is not low.

A good distributor in China or agent knows the domestic market and the orders of multiple customers are superimposed, so it has more bargaining chips for the factory and is also a better choice for small customers.

10. Development trend of the fiber optic distribution box

From the current market and supply point of view, the product development trend of the fiber distribution box has developed in two directions.

The first direction is to make construction faster and simpler, and to save customers’ construction costs.

As shown in this fiber distribution box, it closes the box after the fiber is melted. The user does not need to open the box again, and directly connects to the network signal with the quick connect outside. Once installed, it can be connected to the user’s end with the quick connector only by unscrewing the following connector, which saves labor costs on the one hand, and it is better for the dustproof level without opening the box.

The second direction is more diversified functions, especially in rural areas, where the population density is low, and the number of optical fibers of an optical cable is often unused. The optical cable not only needs to be shunted, but also needs to be connected, so the new type of The fiber box has a connection function to ensure that unused optical cables are forwarded to other regions through the connection again.

Conclusion

The general direction of network communication technology is faster transmission speed, wider transmission bandwidth and more accurate data transmission. All optical fiber communication products should cooperate with it to achieve better results. The fiber distribution box is just a protection device, and its main function is to protect the safety and stability of the optical distribution node.

Its development trend is to ensure the protection performance while continuously reducing costs, and then make construction faster and save labor costs.

Shiningfiber has many years of experience in manufacturing fiber distribution boxes, has a deep understanding of the product,assure product quality, and escort customers to develop the market. We are willing to back up our customers’ strong supply chain.