Now optical fiber communication has become the mainstream method of communication transmission. The market is full of all kinds of optical fiber products, with many categories, complex models and long product lines. Conventional, customized, and improved products coexist, and optical fiber communication technology continues to progress rapidly, and new products will quickly enter the market. How to classify many optical fiber products? This article will be divided into five parts.

Table of Contents

1. Definition

The official definition of optical fiber is optical fiber, a fiber made of glass or plastic, which can be used as a light transmission tool. In the actual application scenario, it is difficult to see the optical fiber. It has been protected by layers, modified, and turned into an optical cable, jumper, pigtail, plc splitter and so on. Therefore, the actual optical fiber is only an integral part of various finished products, and of course it is also a core component. From the product point of view, the optical fiber is of little significance. The optical fiber will eventually form a product chain.

For example: the connection of the optical fiber requires flanges, fast connectors, and the fusion of optical fibers requires the use of fusion splicers, protective sleeve, and fiber connections. The joint closure is needed, the outdoor protection of the fiber distribution fiber needs the distribution box, the indoor patch panel. The fiber signal conversion will use transceivers, optical modules, optical fiber outdoor transmission to outdoor optical cable, indoor to indoor Optical cable and so on.

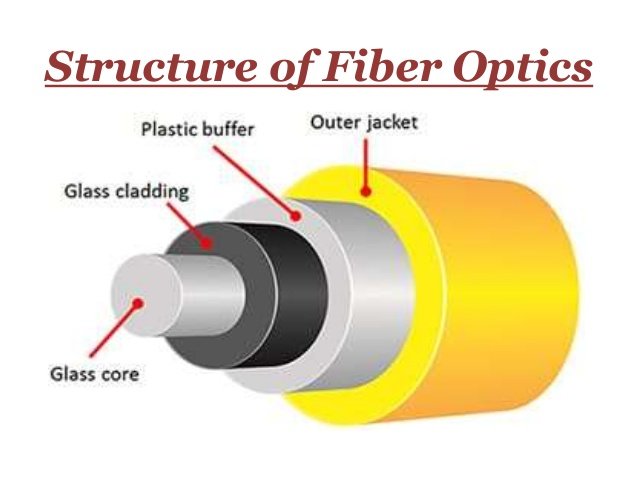

2. Construction of fiber optic

Today we will talk about the cable in optical fiber products. First of all, let’s see how the optical fiber is constructed.

- Fiber Core

Located in the center of the fiber, the composition is high-purity silica with a very small amount of dopant. The refractive index of the core is slightly higher than that of the cladding, and the loss is lower than that of the cladding. The optical energy is mainly transmitted in the core.

- Cladding

Located around the core, the composition is also high-purity silica containing very little dopant. The cladding provides a reflective surface and optical isolation for the transmission of light, and plays a role in mechanical protection.

- Coating

The outermost layer of the optical fiber is composed of acrylate, silicone rubber and nylon. The coating protects the optical fiber from moisture and mechanical scratches.

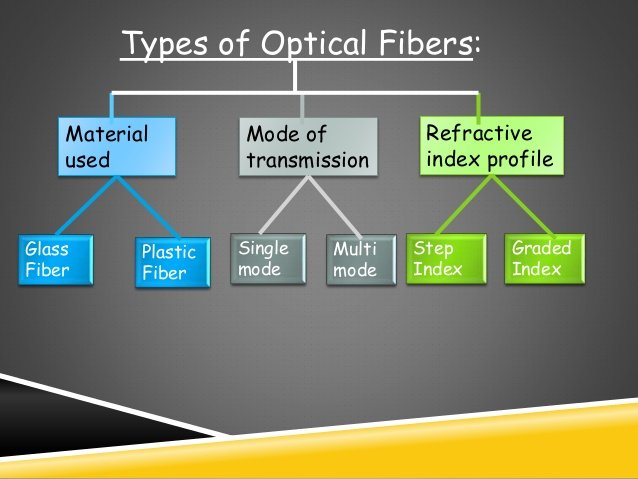

3. The classic classification of optical

This classification is currently the most widely accepted one.The first two categories are easy to understand, and both are relatively well-understood. The third category is based on the refractive index profile and is two ways of multimode fiber optical transmission.

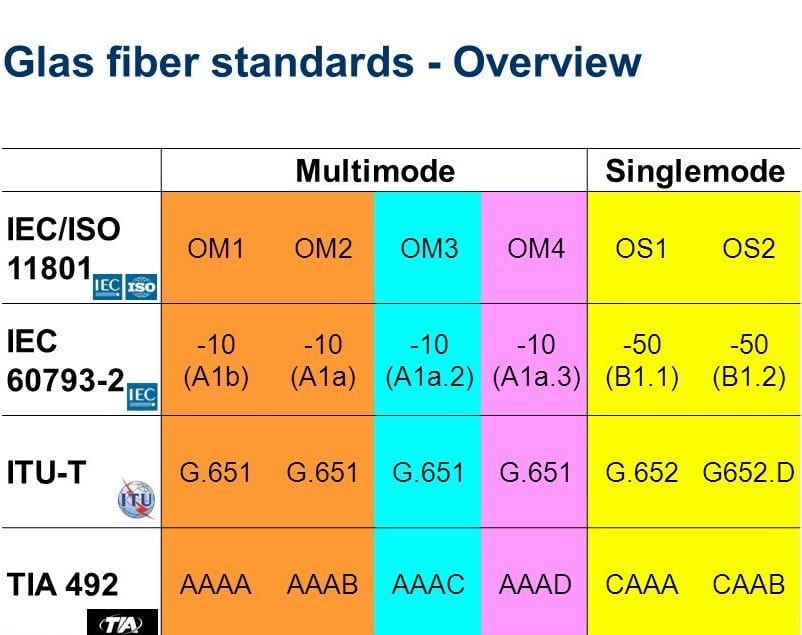

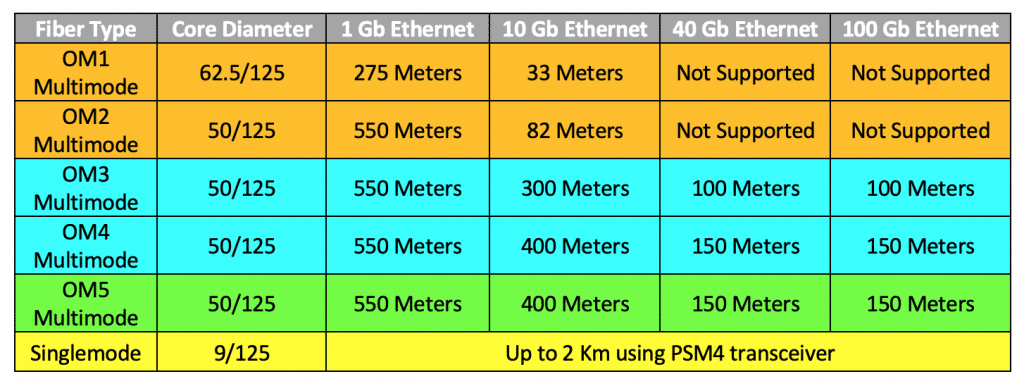

The World Standards Organization has also made a more detailed classification of single-mode fiber and multi-mode fiber:

At present, the actual application is the classification of IEC/ISO and ITU-T. The specific parameters of IEC/ISO11801 classification are as follows,

Because the ITU-T standard content is very complex and very detailed, it will be explained in detail in the following blog.

4. The most widely used product of optical fiber–optical cable

There are many types of optical cables on the market, and the models are complicated and very chaotic. The World Standards Organization ITU-T has also made unified recommendations on the types of optical cables,

GY:Communication indoor (field) outdoor optical cable

GM:Communication Mobile Fiber Optic Cable

GJ:Optical cable in communication indoor (office)

GS:Optical cable in communication equipment

GH:Submarine optical cable for communication

GT:Special optical cable for communication

F:Non-metallic reinforcement

D:fiber optic tape structure

J:Fiber Optic Jacketed Structure

G:Skeleton channel structure

X:Central beam tube structure

T:Grease filled construction

Z:self-supporting structure

B:Flat shape

Z:Flame retardant

Y:Polyethylene sheath

V:PVC sheath

U:Polyurethane sheath

A:Aluminum-polyethylene bonded sheath (A sheath)

S:Steel-polyethylene bonded sheath (S sheath)

W:Steel-polyethylene bonded jacket (W jacket) with parallel steel wires

L:Aluminum sheath

G:Steel sheath

Q:Lead sheath

The tail number behind the model number is the outer sheath code.

For example: a customer needs GYXTA (S) 2-12 optical cable, then according to the above code, you know which optical cable is specified by the customer

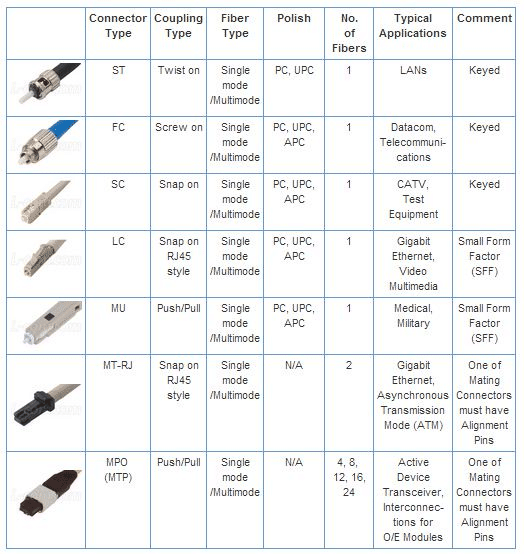

5. Classification of the fiber optic connector

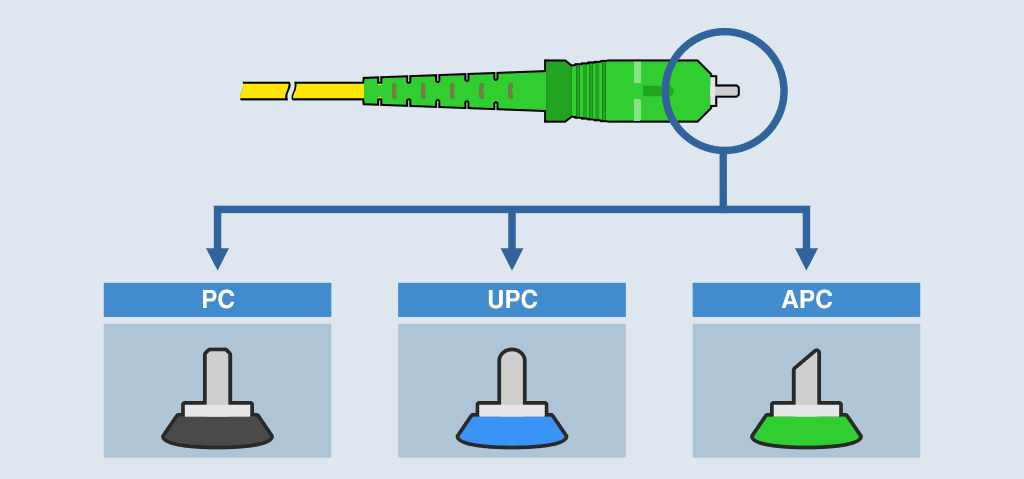

The POLISH of each connector is divided into three categories: PC; APC; UPC. This index must be specified in the requirements. For example, the customer proposes that the SC/APC connector is required. So what is the difference between these three?

As shown,

“PC:Physical Contact”:

The joint cross section is flat, in fact, it is microsphere grinding and polishing, which is the most widely used in telecom operators’ equipment

“APC”:

At 8 degree angle and microsphere grinding and polishing, this model is mostly used in the broadcasting&TV and early CATV. Its pigtail head uses an angled end face to improve the quality of the TV signal. The main reason is that the TV signal is analog for light modulation, when the coupling surface of the joint is vertical, the reflected light returns along the original path.

“UPC”:

The attenuation is smaller than that of “PC”, and it is generally used for equipment with special needs. Some foreign manufacturers use FC/UPC in the fiber jumper inside the ODF frame, mainly to improve the ODF equipment’s own indicators.

Conclusion: Optical fiber is a very simple thing. You can think of it as a glass hair strand. because of cheap price and better performance,It replaces copper cable in optical fiber communication and becomes the main propagation medium.Optical fiber itself does not need to be classified, but there are many products made of optical fiber. Market demand, production technology, changes in application scenarios, etc. cause too many products and complicated models.

The classification is ultimately based on the market application. As long as the use scenario is clear, the product demand is clear. According to the product demand, it is easy to find the existing product category. If there is no existing product, product customization is also very simple.

The end

Shiningfiber specializes in creating the supply chain of optical fiber products for customers. Customers only need to operate their own local market. We provide customers with the most competitive products in the market and strive to become your best Chinese business partner.If you need any help, feel free to contact us, Or let me know by leaving a comment below.